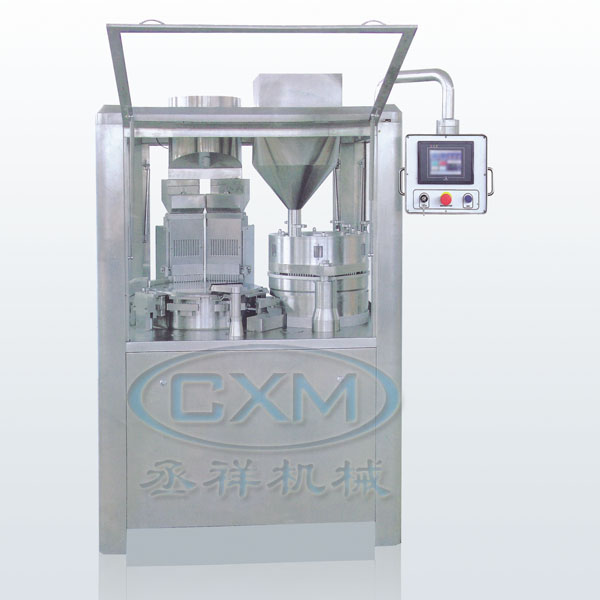

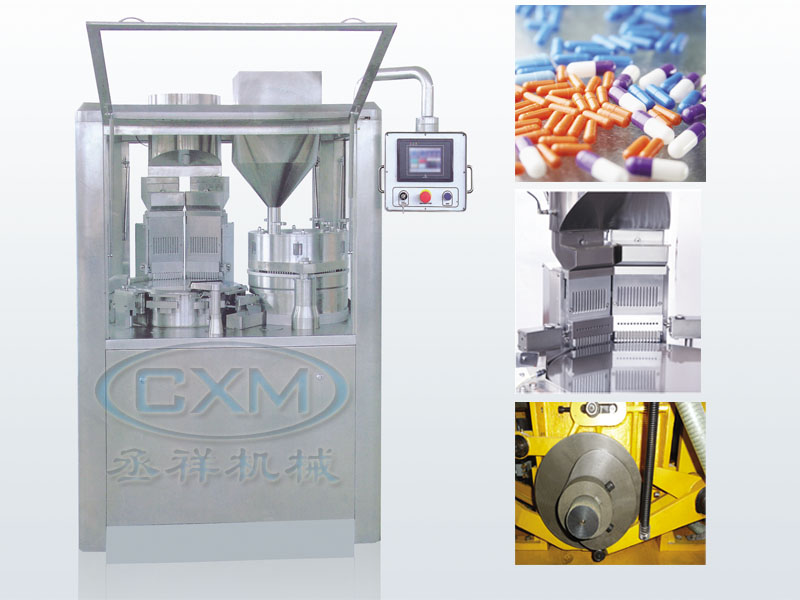

This model is an intermittent motion and hole plate type automatic capsule filling equipment. It adopts optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP. It has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stably running etc. It can finish the following motion at the same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and die hole cleaning, etc. This machine is designed for meet the volume-production on the basis of NJP1200 automatic capsule filling machine. It increases the lifting mechanism that it is easy to clean. It saves the cot and manpower for the enterprise that needs volume- production.

Main Features:

It has been improved the inner design turret, and imports beeline bearing for each machine from Japan directly, so that it can be sure a longer usage-life and precision of machine.

The working station cam runs under the good lubrication condition, and maintains the inner lubrication of cam slot to a full extent, increasing the pressure pulverization oil pump, thus extends the operation life of the spare parts.

It is controlled by the computer, has a stepless timing with the frequency-conversion, the numeral showing makes an easy operation and clear appearance.

The multi-bore dosing brings a precision dosage (it is controlled around ±3.5%); the good capsule applicability makes a higher capsule qualified rate (≥99%). It can be filled with the Chinese tradition medicine and Western medicine.

It has protector equipment for the operator and the machine. It has automatic pause equipment when it is lack of the material. It has a steady and safe working. It is the best choice for the hard capsule filling production.

|

Model

|

NJP-3200

|

||

|

Capsule Size

|

00#-5#

|

||

|

Power Supply

|

380V, 50Hz, 3 phase, 4 wire,7.62 kw

|

||

|

Water Supply

|

500L/H, 0.2-0.10 MPA

|

||

|

Dust Collector

|

160 M3/h

|

||

|

Noise

|

<75 dBA

|

<75 dBA

|

<75 dBA

|

|

Dimension (mm)

|

1375*1345*(2000+250)

|

||

|

Net Weight (kg)

|

1500

|

||

|

Filling Percentage

|

〉99.5%

|

||