Applications:

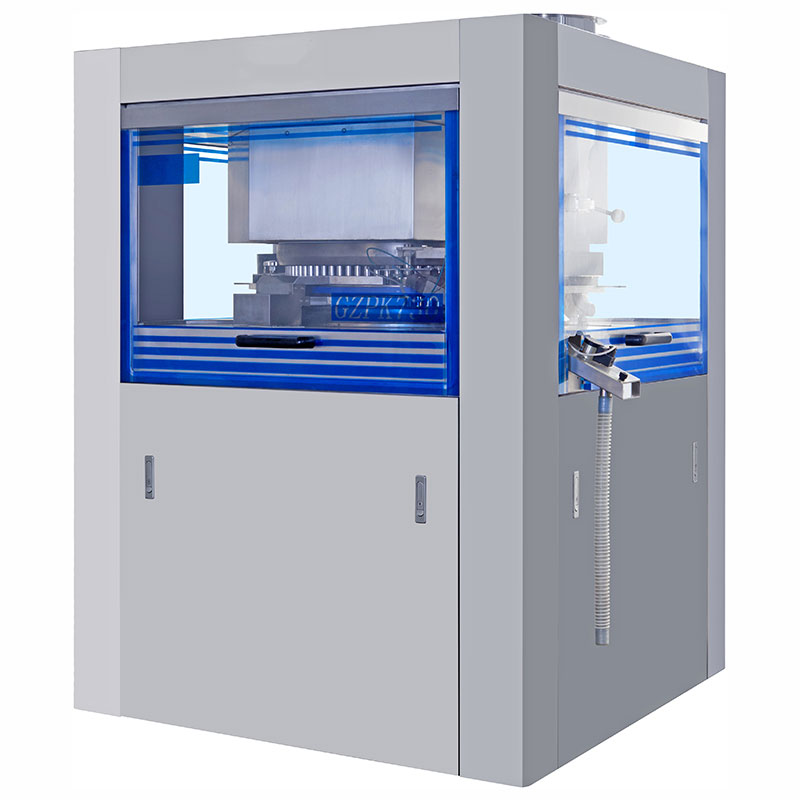

GZPK370 series high-speed rotary tablet press is a new single press high-speed tablet press developed by our company. It has the characteristics of large pressure, novel appearance, reasonable structure, convenient operation & maintenance, stable & reliable operation, varied & comprehensive electrical functions. It meets GMP requirements and is an ideal upgrading model instead of outdated ones.

Usage:

This machine is a kind of automatic rotary tablet press, which is suitable for electronic, food, chemical, pharmaceutical and other industries to continuously press various powder or granular raw materials. The machine is suitable for pressing a variety of tablet products, such as medicine tablets, milk tablets, calcium tablets, effervescent tablets and other difficult shaping tablets.

Features:

1. It adopts high pressure structure, main pressure and pre-pressure are both 100KN, adopts force feeder which is suitable for powder direct pressing or pressing difficult forming materials.

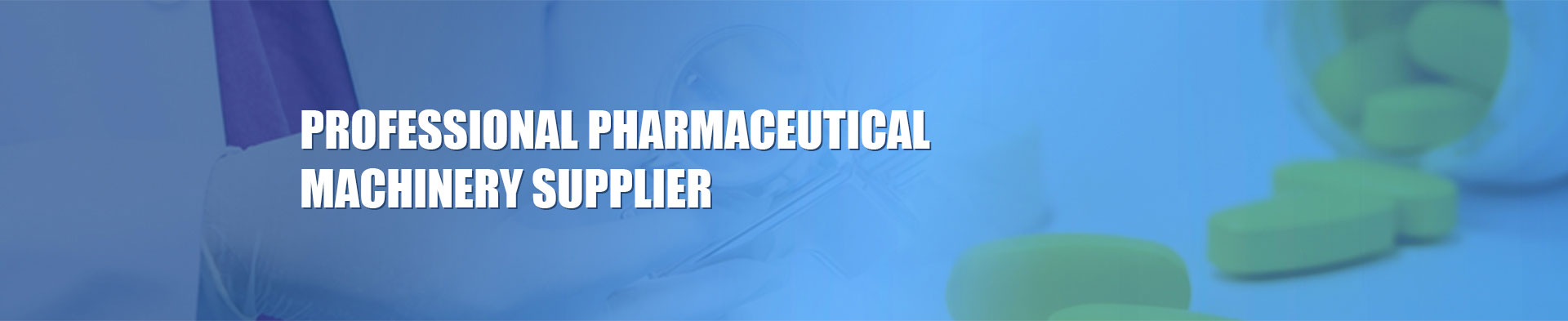

2. Automatic control without handwheel adjustment, servo motor is used to adjust main pressure, pre-pressure and filling quantity.

3. Single sided output, small occupying area.

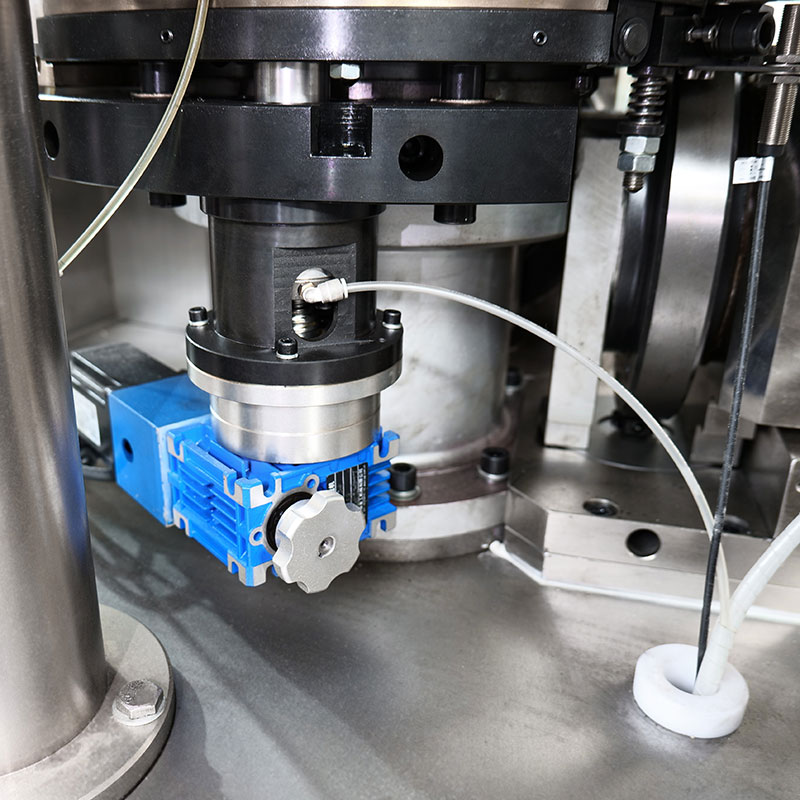

4. Machine outer cover is totally enclosed and made of stainless steel. All the parts in contact with drugs are made of stainless steel or treated with special surface treatment, which are nontoxic, corrosion-resistant and conform to GMP standards.

5. Tablet compression chamber is closed with transparent plexiglass and stainless-steel table, it can be opened completely, which is easy to change mold and maintenance.

6. Main pressure and pre-pressure are equipped with pressure sensors, which can real-time display the working pressures of each punch, also can set the limit of pressure protection, so as to automatically stop the machine once over-pressure occurs.

7. Online pressure detection and automatic adjustment of tablet weight, with tablet rejection function.

8. Touch screen and PLC control, easy to operate, various menus, safe and reliable.

9. Automatic lubrication system is adopted to fully lubricate the pressure wheels, tracks and punches, so as to extend the service life and reduce the parts wear.

10. Equipped with 11KW high-power motor and high-precision reducer to achieve stable power output.

11. Equipped with a variety of safety protection devices (emergency stop, over-pressure, punch sticking, material level detection, door & window interlock protection, etc.)

12. CFR211 electronic signature and data export function are optional.

Model | GZPK-26 | GZPK-32 | GZPK-40 | GZPK-44 | |

Numbers of Punch Stations | 26 | 32 | 40 | 44 | |

Punch Type | D | B | BB | BBS | |

Max main pressure (kN) | 100 | ||||

Max pre pressure (kN) | 100 | ||||

Max Tablet Diameter (mm) | Round tablet | 25 | 18 | 13 | 11 |

Irregular tablet | 25 | 19 | 16 | 13 | |

Max filling depth (mm) | 18 | 16 | |||

Max Thickness of Tablet (mm) | 8 | 6 | |||

Max Turret Rotation Speed(r/min) | 90 | 100 | 110 | 110 | |

Max Production Capacity (tablets/hour) | 140000 | 192000 | 264000 | 291000 | |

Motor power (kw) | 11 | ||||

Dimensions (mm) | 1380×1200×1900 | ||||

Weight (kg) | 1800 | ||||